Start / Stop Cycles

Changes are happening very quickly in the electric power industry.

The word “transformation” is defined as a thorough or dramatic change in form. The advent of renewables has transformed the mix of power generation assets feeding the grid. This transformation is creating opportunities for owners of traditional generation assets, including industrial gas turbines. Vintage gas turbine owners now have new opportunities to generate significant additional revenue from what were previously unproductive assets. With this opportunity comes new problems.

Problem… Keeping up with Start/Stop Cycles

The energy industry is increasingly embracing renewables; an impactful trend is emerging - gas turbine operators are having to multi-start machines, sometimes as often as twice a day. Multi-starting has become the new norm with 10-minute ramp-up periods. It is not uncommon to hear that some operators are having over 500 starts per year.

Vintage gas turbines have been used in peaking applications for years, but this dramatic increase in the frequency of starts means that tracking starts based component life has become a much more critical requirement to maintaining unit reliability and optimizing revenue from these units.

Keeping track of as many as 500 starts per year and the fired factored hours on multiple units has become a challenge. And, no amount of skills in managing Excel spreadsheets of parts will be adequate in suppressing downtime due to unplanned outages.

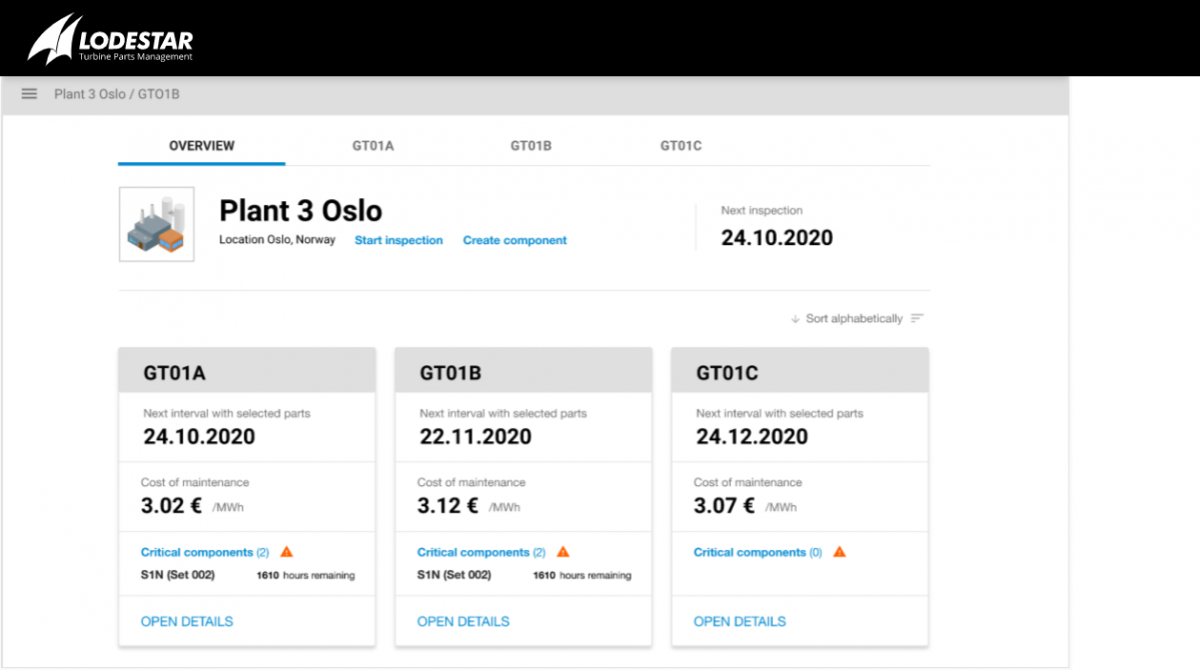

Solution… Lodestar Turbine Parts Management™

Lodestar is Predictive Maintenance Software Designed for Component Life & Outage Tracking of Gas Turbines Parts.

Lodestar automates the capture and presentation of historical data and the calculation of remaining critical parts life into a user-friendly interface

These features allow users to:

- Significantly improve critical part management.

- Increase maintenance personnel productivity.

- Reduce overall maintenance costs.

- Minimize outage downtime and delays.

- Share unit information with key service personnel on any internet-connected device.

Lodestar provides service and maintenance managers, procurement managers, site personnel and fleet owners a very clear picture of what parts are driving upcoming outage decisions and the full range of parts repair/replace options currently available within the fleet.

The Lodestar scenario builder tool allows users to simulate different unit operating scenarios, including stop/start cycles to predict the impact on parts life and to optimize outage planning decisions.

To learn more and sign up for a free no-obligation presentation, go to TTSLodestar.com.